Value Stream Mapping and its Benefits

Value Stream Mapping is a proven methodology that enables organisations to gain a holistic view of their processes, identify the root causes of problems, and eliminate them with precision and confidence. It clearly explains how value flows through the process and helps organisations focus on eliminating non-value-added activities. With VSM, organisations can streamline operations, reduce costs, and improve customer satisfaction while gaining a competitive edge in their industry.

- There are several benefits of using VSM. For instance, it can help organisations to:

- Identify waste and inefficiencies in their processes

- Improve communication and collaboration among teams

- Reduce lead time and cycle time

- Enhance productivity and efficiency

- Improve product quality

- Increase customer satisfaction

VSM is a highly effective tool that enables companies to create a detailed map of their end to end value stream(s), from the supplier to the customer. With this comprehensive picture, businesses can quickly identify areas of improvement and make necessary adjustments. By leveraging VSM, companies can maximise their value creation and stay ahead of the competition in their respective markets.

Major Benefits of Value Stream Mapping

- Improved Process Visibility: VSM provides a clear, high-level overview of processes’ operations, making it easier to spot inefficiencies.

- Waste Reduction: By highlighting non-value-added activities, VSM helps reduce waste in the production or service delivery.

- Enhanced Communication: VSM encourages cross-functional collaboration, fostering better communication among teams.

- Lead Time Reduction: Identifying and eliminating bottlenecks and non-value-added steps can significantly reduce lead times.

- Cost Savings: Streamlining processes and reducing waste can result in cost savings, benefiting the bottom line.

- Quality Improvement: Organisations can improve product or service quality by focusing on the value-adding steps.

- Customer Satisfaction: Shorter lead times and higher product quality often increase customer satisfaction.

Implementing Value Stream Mapping

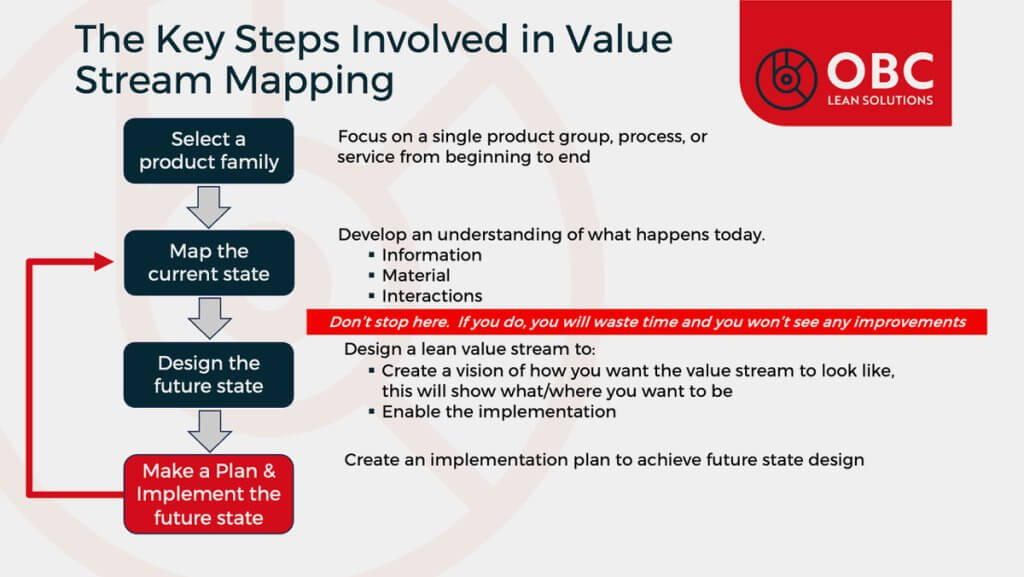

To effectively implement Value Stream Mapping, an organisation should follow the steps outlined below:

- Select the Value Stream: Choose a specific process and product group that is to be the focus for improvement.

- Gather a Cross-Functional Team: Bring individuals from different departments to ensure a holistic view of the process

- Map the Current State: Create a visual representation of the current process, identifying all material and information flows, activities, processes, cycle times and inputs/outputs.

- Identify Waste: Mark non-value-added activities and areas where waste occurs.

- Develop the Future State Map: Envision and design an improved process that eliminates waste and improves efficiency and set a target timescale for its implementation

- Implement Improvements: Execute the changes needed to move from the current state to the future state.

- Measure Progress: Continuously monitor and measure key performance indicators to ensure the improvements are sustained.

Challenges of Value Stream Mapping

Implementing VSM can be challenging, and several factors should be considered. One of the most significant difficulties is the need for accurate data and a thorough understanding of the processes. Without this information, it can be challenging to identify improvement opportunities or accurately measure the impact of changes. Therefore, gathering and analysing relevant data is critical to ensure that the VSM process is effective. If organisations don’t have this data to hand they can still develop the current state VSM and create a future state value stream map that shows what information and data needs to be created.

Another significant challenge organisations may face is resistance to change from employees comfortable with the existing processes. This can be especially true when changes impact job roles or responsibilities. It is essential to involve employees in the process and communicate the goals and benefits of VSM to address this challenge. By doing so, employees can understand the importance of the changes and contribute their knowledge and expertise to the process.

In addition, organisations should ensure that their VSM process is aligned with their overall business strategy and objectives. They should also establish clear performance metrics to evaluate the process’s success and measure the impact of changes.

Conclusion

Value Stream Mapping is a visual tool used by organisations seeking to deploy a Lean strategy and it involves creating a detailed map of all the steps and processes involved for a specific value stream. It helps to identify waste, eliminate non-value-added activities, and streamline the process to make it more efficient. By implementing VSM, organisations can significantly reduce lead times, cut costs, and improve quality. The mapping process provides a clear understanding of a process’s current state and helps identify areas where improvements can be made. Implementing VSM can be challenging, especially in complex processes, despite its many benefits. However, the potential benefits make it a valuable tool for organisations seeking to optimise their operations.